For our equipment with shells, the location for adding or replacing 3D printing materials is on the side door. Simply open the door, place the materials inside, and insert them into the feed inlet.

After printing is complete, remove the support structures from the model, then begin sanding to smooth the surface until there are no noticeable protrusions. Afterward, apply the appropriate type of paint to achieve the desired finish.

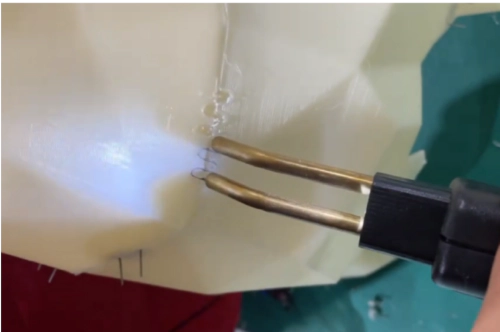

You will need two items: a plastic repair welding gun and hot melt nails. The welding gun heats the hot melt nails so that they can bond with the 3D printed parts. This process will help fix the two 3D printed parts together. You can either search online or contact us directly to obtain the welding gun and hot melt nails.

We support almost all major languages.

No, but we offer consumables at factory prices, which are generally cheaper than those available locally. You are also free to purchase the materials yourself, as long as the filament diameter is the same.

Our machines come with a one-year warranty.

The printer is an industrial-grade machine, capable of running for extended periods without interruption.

This generally depends on the price of the consumables you use and the model’s structure. Under normal circumstances, the average cost to print a model of approximately 1*1*1 meters should not exceed USD 100, which greatly depends on the material you use and the model’s design.

Contact us at any time. We can provide you any support you need.

BYT® was founded in 1996, is a leading brand in large industrial 3D printer area, serves clients in 150+ countries.

© 2025 Copyright BYT Technology Co. 山东察九